Advancements in commercial printing have made it possible to complete printing jobs faster than ever. There are two conventional methods of printing on corrugated boxes: flexo printing and litho printing. Which one is best? The answer depends on the specifics of your project, as each process is ideal for different needs.

Learn more about the pros and cons of flexo vs. litho printing as well as the similarities and differences so you can make an informed decision for your next printing project.

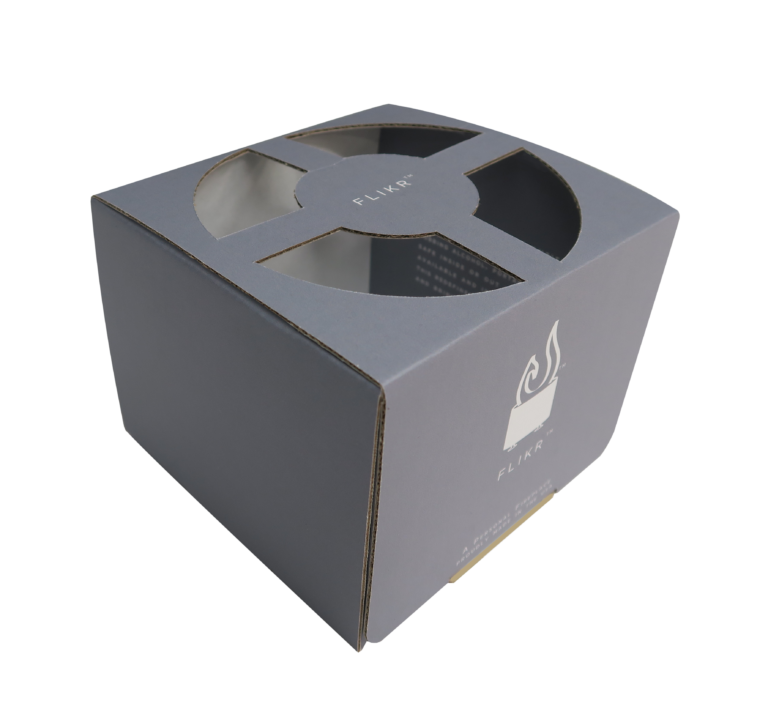

Flexographic printing, also known as flexo or surface printing, is a method of printing in bulk that uses flexible relief plates. These plates are typically made from rubber or polymer and are used with quick-drying ink.

The ink is transferred from an ink pan and applied on an anilox roll. An anilox roll is a hard cylinder made from aluminum or steel with a ceramic outer layer and dimples. This is used to uniformly distribute the ink on the plates. The plates act like a large stamp, transferring images onto corrugated boards. The boards are then run through a dryer to prevent smudging.

Flexo is a very common printing method that uses a variety of substrates including foil, paper, non-woven and film.

The benefits of flexo printing include:

There are a few disadvantages to choosing flexo printing:

Lithographic printing is a type of offset printing that takes several steps to complete. With this method, ink is applied to a printing plate. Then, the printing plate is used to apply the ink on a rubber blanket through multiple ink rolls. Finally, the ink is applied to the substrate from the blanket. With this indirect form of printing, the image is not printed directly onto the substrate from the plate like with flexo printing.

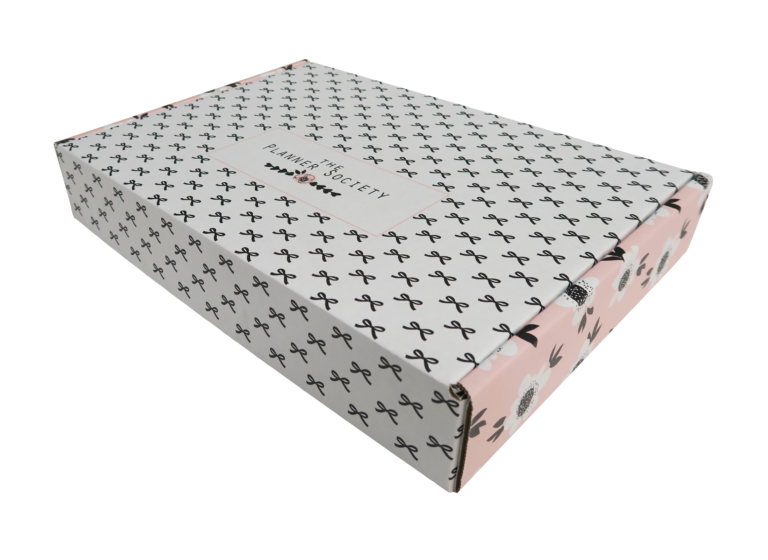

There is also lithographic lamination, where the print is made on paper and then laminated on the box for a glossy, premium finish.

There are several benefits to litho printing:

A few disadvantages of this process include:

Both flexo and litho printing are conventional bulk printing methods that use printing plates, and both methods can be cost-effective for more basic large print runs. There are also some key differences between the two processes.

Litho printing can accommodate embellishments like foil stamping and embossing for a higher production cost. Flexo printing is more straightforward, and properly stored image carriers can be reused numerous times before needing to be replaced.

Flexo is a versatile option that can print on both porous and non-porous surfaces, which makes it ideal for many different substrates. Litho requires smooth, flat surfaces since the image needs to be pressed on the substrate. Both litho and flexo can use oil-based inks, but litho provides greater color detail and variety.

Which printing process should you choose? Generally speaking, litho printing is better for full-color printing with detailed patterns and can accommodate more finish options. Flexo printing is a more direct process that can provide faster printing times and lower costs, but without the detailed colors and image quality of litho printing.

The answer really depends on the specific needs of your project. Factors such as quantity, quality and color requirements, desired completion time and budget all contribute to making the decision between flexo and litho printing.

If you need custom box printing, Custom Boxes Now can help. Simply send us the details of your project, including measurements, images or a physical sample, and our designers will engineer the perfect solution. You can also use our online design tool to receive a quick estimate.

We produce everything in-house, from the design to the production and delivery of your custom boxes. As a result, we can provide exceptional quality control compared to companies that outsource their processes. To get started, use our box configuration tool or contact us for more information today.