Are you wondering how to make custom boxes for shipping? Are you unsure if you even need to bother? Let’s explore this topic together for a bit…

The age of digital marketing and eCommerce has presented a massive problem-slash-opportunity for merchants around the globe. The first, and perhaps most important, thing to note is that with this now-standard means of offering and shipping products, packaging is more important than ever.

Don’t believe us? Take a look at these little tidbits of info…we think you’ll find them rather insightful. According to a recent survey:

Yet despite these clear indications of just how important custom packaging is to consumers, and how much opportunity it presents to retailers…only 11% of consumers are totally satisfied with the eCommerce packaging they receive today.

Convinced that premium, custom packaging may be a smart move for your brand? Read on to learn everything you need to know about how Custom Boxes Now can help you make the switch to a smarter, custom box that will help you improve profits and make the sale.

LEARN HOW TO MAKE CUSTOM BOXES FOR SHIPPING IN 5 EASY STEPS:

In addition to making the process of creating custom boxes easy with five steps, we’ve got a few other things going for us. At Custom Boxes Now, we have nearly 60 years of experience as a retail packaging industry leader. During these decades, we’ve fine-tuned our experience in designing and manufacturing custom printed shipping boxes. Today, we’re known for an on-time record of over 99% — that allows our clients to keep up with their packaging needs without any productivity breaks.

How do we consistently meet our clients’ time demands? In large part, our reliability is due to our entirely in-house process. Custom Boxes Now operates under one roof, based in Minneapolis, MN. Every stage of the process happens in our facility — which lets us maintain total oversight over the details, quality and speed of each custom-size shipping box. As an ISO 9001:2015 certified company, our standard of quality speaks for itself.

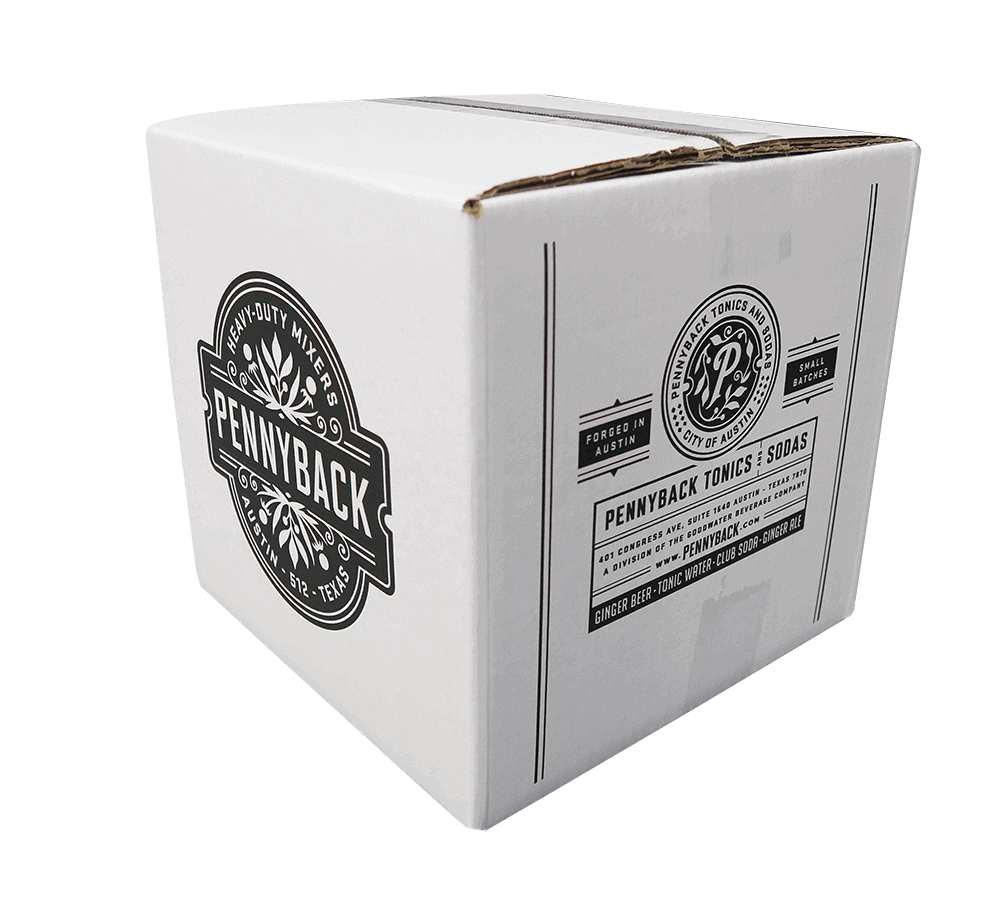

Our turnkey process includes a variety of versatile printing options depending on your company’s packaging preferences. If you decide to opt for custom shipping boxes with a company logo, for example, we can handle your printing needs in-house. We’ll only encourage you to get the services you need. We know that you’ve got a budget to meet, which is why we aim to offer the most cost-effective packaging plans possible.

When you work with Custom Boxes Now for your packaging solutions, you can enjoy benefits such as:

We’ve made it as easy as possible to order custom printed packaging so you can be boxing your products and increasing your revenue in no time at all. Still have questions about the process? Reach out to Custom Boxes Now any time for step-by-step guidance and help on creating your custom packaging.