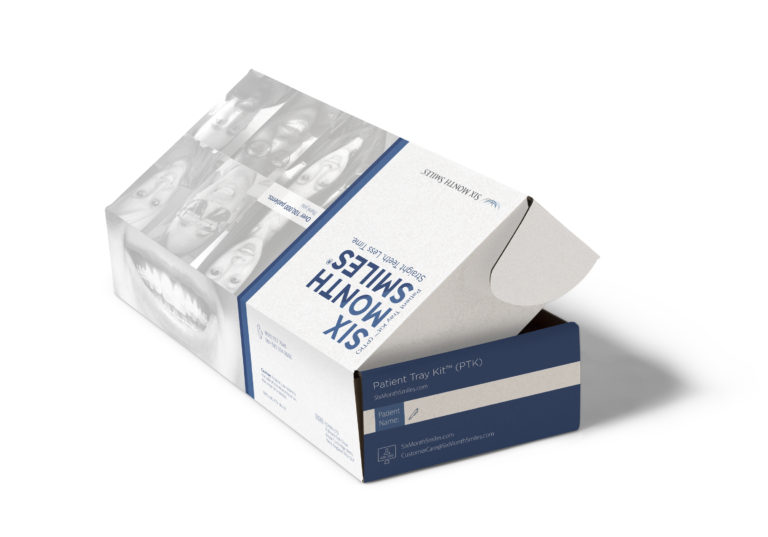

One of the first things a consumer notices is your packaging. It’s arguably the single most important part of any marketing plan. Studies consistently find that the design of your packaging is what people remember long after they purchase your product and toss the box.

Keeping your packaging up-to-date and modern is essential to your brand identity. Many companies put off a redesign or a packaging modification because of the costs they believe are involved. But with the advancement of digital printing, this is no longer necessary.

Read on for more reasons why it’s easy to keep up with the packaging times – digital printing means your brand can remain looking fresh and ready to sell.

Digital cardboard printing involves applying ink directly onto the substrate, instead of transferring the image via print plates. This is usually done using a digital printer that can print the design line by line. A wide range of color options means you can print virtually any design onto your box for a vibrant and photo-quality finish. Because the process doesn’t use print plates, digital printing can significantly speed up your printing without sacrificing quality. In fact, digital printing offers premium quality and control.

The process of digital printing on corrugated boxes is not too different from how you print something at home. Using digital files and an industry-grade printer, packaging manufacturers can print incredibly high-quality graphics directly onto your substrate. Because of the digital access and lack of printing plates, you can select from the full CMYK color spectrum as well as gradients and detail effects.

Digital printing has many perks for businesses. With a full range of color options, tight turnarounds and a high-quality finish, digital prints are an increasingly popular choice. They’re particularly beneficial if you need:

Custom Boxes Now offers three processes for printing images and messaging onto your packaging or display structures. Each of these printing styles involves a unique process and leads to a slightly different result. Check out these three methods to decide which one may work best for your printing needs:

Each style of box printing has its own perks depending on your specific needs. Digital printing offers a variety of unique benefits that will help your custom boxes leave a lasting impression. Beyond the speed, flexibility and incredible photo quality finish, there are many more advantages to going digital!

Read on for more reasons why it’s easy to keep up with the packaging times – digital printing means your brand can remain looking fresh and ready to sell.

Most brands offer more than one specific product, and many have several variants within the same line. If this is the case with your product, your design and branding should reflect that. Keep the similarities (logo, colors, other branding identifiers) while showing the differences in your products’ individuality. This way consumers can immediately recognize your brand while seeing the differences in your products. This is so much more manageable when using a digital printing option.

Special sales and one-time-only deals are other good examples of why digital printing is the way to go. Because you’re printing digitally, you can alter anything for special events without the added expense of starting from scratch. Swapping out a logo size or adding an extra element (to highlight a promotion) has never been easier. Changes in printing can be done more often, allowing for one-time or shorter print runs.

In the past, the process of tooling was your only option for printing, and it was costly and time consuming. Tooling is a more expensive method of printing that, at one time, discouraged companies from making changes to their packaging even if the outcome would prove beneficial. This is yet another example of how and why digital printing taken the packaging industry by storm – simply put, it’s both more efficient and more cost effective. Changes can be made easily, seamlessly and more often when you’re doing so digitally.

Your brand is what you want consumers to remember. And building it up depends a lot on your design and packaging. Digital printing allows for an exact and precise base model to be reconfigured and repurposed for seasons, sales and new product launches. Think of digital printing as a template to build upon each time you need to make a change. You don’t have to reinvent the wheel every time you need new or more packaging. The key is to maintain your brand look across your entire line of products. Remember, successful branding will be easy to recognize and eye-catching.

Digital printing means each individual product design can be perfectly customized. Packaging can be created in any size, and visually, you can make your colors really pop for maximized recognition. Specialty digital printing orders keep customers coming back for more.

Boxes come in any size you could possibly need. The benefit of digital box printing is that it can be used for any configuration, with very few restrictions. Digital printing adheres to corrugated packaging and other materials.

Store displays that are used to advertise and sell products are usually put in high traffic areas of retail marketplaces to attract customers. The digital printing on displays can represent and compliment your product packaging, encouraging a sale. The design and colors can really make a difference, and having a cohesive presentation that matches your packaging and branding can make quite the impression on consumers, and that will keep them coming back.

These days, digital is the most cost effective way to go when designing your box or packaging – it allows for variation and updates whenever you need them. The savings on turnaround alone can really add up. Today’s printing solutions allow brands to reach out and grab consumers’ attention. Now is the time to check out digital and see how it can help build your brand while selling more products. Create your own one-of-a-kind boxes using our custom box configuration tool!

Looking for help with your digital box printing? Custom Boxes Now is here for you! Reach out today to learn more about how digital printing can take you to the next level.